views

Identification basis of non high quality galvanized steel sheet

From the quality requirements of galvanized steel plate,its inspection mainly includes two aspects:one is appearance quality,the other is quality inspection.Appearance quality includes packaging,size,weight,surface appearance,etc;Quality inspection includes galvanizing quantity,mechanical properties,chemical composition,etc.Therefore,the inspection and identification of non high-quality products are also considered based on these aspects.

Packaging of galvanized steel sheet

Observe whether the goods are in export standard packaging,simple packaging or bare packaging;Is the package intact or damaged.Generally speaking,the packaging of high-quality products is relatively complete;However,we can not unilaterally believe that the incomplete packaging is non high-quality products.

Specification and dimension of galvanized steel sheet

Whether the specifications and dimensions of the whole batch of goods are consistent,and whether the nominal size of the goods label is consistent with the actual size of the goods.For high-quality products,most specifications and dimensions are the same.

Weight of galvanized steel sheet

Including tare and net weight.Check whether the weight of the whole batch of goods is consistent with the contract requirements.

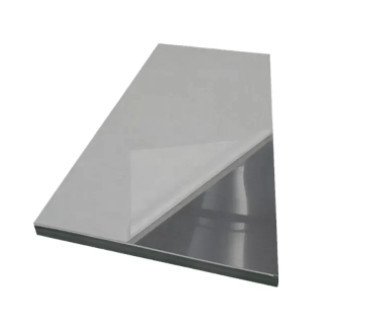

Appearance of galvanized steel sheet

Observe whether there are defects on the surface of the goods that affect the use.As the appearance defects of different goods are different,considering the production process and finished product packaging of hot-dip galvanized steel plate,there may be some surface appearance defects of hot-dip galvanized steel plate:original plate defects,black spots,white rust,uneven galvanized layer,accumulation of galvanized layer,slag inclusion,scratch and scratch,chromic acid dirt;The main purpose of post-treatment of electro galvanizing is to improve the surface painting performance and corrosion resistance of galvanized sheet,so as to prolong the service life of galvanized sheet.Post plating treatment mainly includes phosphating treatment and chromizing treatment.In addition to the defects of the original plate,improper operation of any process will cause quality problems.General surface defects include pinholes,pits,burrs,blisters,peeling,spots,internal and external surfaces,and local non plating.In addition to the above surface defects,the coating surface sometimes has defects such as damage,scratch,white rust,roll mark,pit,crease,black spot,unclean salt trace,water trace,erasable or brown,brown passivation film,dendritic,sponge and stripe coatings.All these defects will have a certain impact on the use of galvanized sheet.

Quality of galvanized steel sheet

Inspect the galvanized quantity,mechanical properties,chemical composition and other indicators.If one or some of these indicators are found to be inconsistent with the nominal value of the goods label,it can be considered as unqualified products and can be identified as non-high-quality goods.Based on the above five factors,the quality of the goods can be comprehensively evaluated.

The above is the description of the identification basis of non high-quality galvanized steel plate.Every step of siyoute's products is carefully supervised and managed to ensure that customers can buy satisfactory products.Welcome to consult.

Tag:Packaging of galvanized steel sheet,Specification and dimension of galvanized steel sheet,Weight of galvanized steel sheet,Appearance of galvanized steel sheet,Quality of galvanized steel sheet

Comments

0 comment